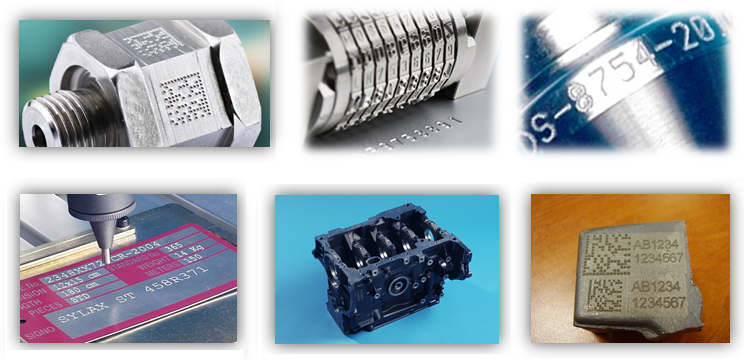

LASER - DOT PEEN - SCRIBING MARKING INKJET PRINTER & AUTOMATION SYSTEMS

|

WELCOME PRODUCT IDENTIFY & TRACEABILITY LASER TECHNOLOGY

Works by electromechanically striking a carbide or diamond stylus assembly against the surface of a part to be marked. The result is a succession of dots to create digits, text, logos, and 2D data matrix codes. Each such dot is the result of a pulsed current that runs through a solenoid, punches a magnet toward the surface, and subsequently returns the stylus to its starting position, awaiting the next pulse. Because each pulse occurs in only a fraction of a second, an entire 2D data matrix code, for example, can be completed in seconds (depending on the size). SCRIB TECHNOLOGY

Scribing is a marking process whereby the mark (text, logo, codes) is produced by a carbide or diamond tip that penetrates and indents the surface. This produces a deep groove that forms continuous lines across round, concave, flat, or arched surfaces, and on almost any material. Also called "drop and drag" or "scratch marking," scribing technology is an ideal choice for applications where noise level limitations are imposed. If dot peen markers are considered too noisy when used on steel pipe, for example, a pneumatic scribing machine might be preferred. SIC Marking's scribing technology guarantees a high quality mark and is ideal for requirements that include Optical Character Recognition (OCR). |